Categories

Contact Us

Fax:0577-66991955

Email:info@huanqiuvalve.com

Add:Sanqiao Industrial Zone, Oubei Town, Wenzhou, Zhejiang, China

International Trade Department: Mike / David / Sara / Ally

Pneumatic actuated forged steel ball valve

Product Description

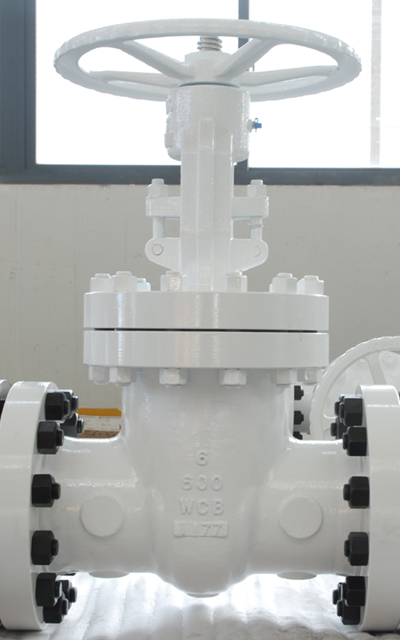

Pneumatic actuated forged steel ball valve

DESIGN FEATURES

Size range: 2" to 56"

Rating class: ASME 150-300-600-900-1500-2500 ANSI

Forged body & closure: WELDED

Seats: Soft seated or Metal Seated with Tungsten Carbide Coating or Chrome Carbide Coating

Self relieving seats or double piston effect seat (DIB-1 or DIB-2)

Anti blow-out stem & antistatic device

Fire safe: API 6FA / API 607 / ISO 10497

Materials in accordance to NACE MR 01.75

Underground application: Valves installed underground or in remote locations can be operated with an optional extended stem. All the drain, vent and emergency sealant connections can be operated using extended connecting pipes firmly attached to the stem protective cover

Fully welded ball valves comply with API 6D / ISO 14313 requirements and with all the relevant industry standards and codes (ANSI, API, ASME, BS, ISO, NACE, PED and others). The weldings of the body are perfomed and qualified according to ASME Section IX; non-destructive examinations (NDE) are performed in compliance with ASME VIII Division 1 and 2.

Material Specifications

Body/Cap: A105, LF2, A182 F304, F316, F304L, F316L, F51

Ball: A105+ENP, LF2+ENP, A182 F304, A182 F316, A182 F304L, A182 F316L, A182 F6a, F51

Stem/Trunnion: A105+ENP, A350 LF2+ENP, A182 F304, A182 F316, A182 F304L, A182 F316L, A182 F6a, F51

Seat Retainer: A105+ENP, A350 LF2+ENP, A182 F304, A182 F316, A182 F304L, A182 F316L, A182 F6a, F51

Seal ring: PTFE / RPTFE / NYLON / VITON / PEEK / metal to metal

huanqiuvalve

huanqiuvalve huanqiuvalve

huanqiuvalve