Categories

Contact Us

Fax:0577-66991955

Email:info@huanqiuvalve.com

Add:Sanqiao Industrial Zone, Oubei Town, Wenzhou, Zhejiang, China

International Trade Department: Mike / David / Sara / Ally

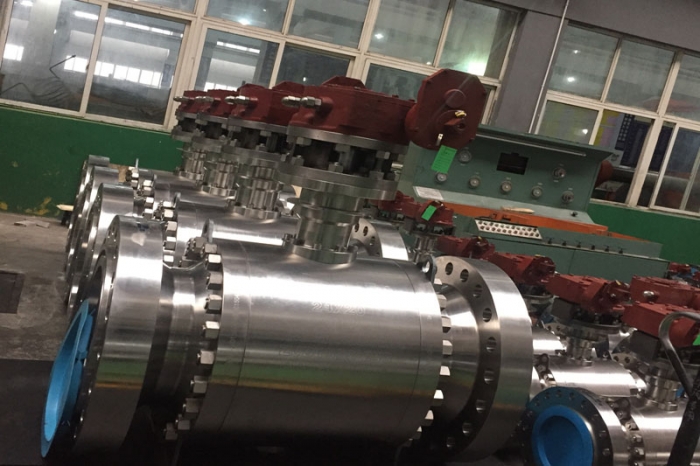

Forged duplex stainless steel trunnion mounted ball valve

Product Description

In comparison to the conventionally austenitic stainless steel grades, the forged duplex stainless steel trunnion mounted ball valve have a much higher tensile strength. The combination of good mechanical properties in combination with good weldability is the reason why 2205 Duplex Ball Valves can be used in an as welded condition.

Material Specifications

Body/bonnet: Ferritic-Austenitic Stainless Steels F50, F51, F53, F54, F55, 57, F60, F65, F68, F69

Ball: Ferritic-Austenitic Stainless Steels F50, F51, F53, F54, F55, 57, F60, F65, F68, F69

Stem/Trunnion: Ferritic-Austenitic Stainless Steels F50, F51, F53, F54, F55, 57, F60, F65, F68, F69

Seat Retainer: Ferritic-Austenitic Stainless Steels F50, F51, F53, F54, F55, 57, F60, F65, F68, F69

Seal ring: PTFE / RPTFE / NYLON / DEVLON / PEEK / metal to metal

Main features: 1. Solid ball, 2. Anti-fire safe design, 3. Anti-static device, 4. Free leakage of body Sealed construction, 5. Low torque in operation, 6. Double block & bleed (DBB), 7. Emergency sealing, 8. Extension stem on request, 9. Automatic body cavity relief, 10. Various driving types: gear, lever, electric, hydraulic, pneumatic, gas over oil.

huanqiuvalve

huanqiuvalve huanqiuvalve

huanqiuvalve