Categories

Contact Us

Fax:0577-66991955

Email:info@huanqiuvalve.com

Add:Sanqiao Industrial Zone, Oubei Town, Wenzhou, Zhejiang, China

International Trade Department: Mike / David / Sara / Ally

Double flanged butterfly valve, DN1400, PN16

Product Description

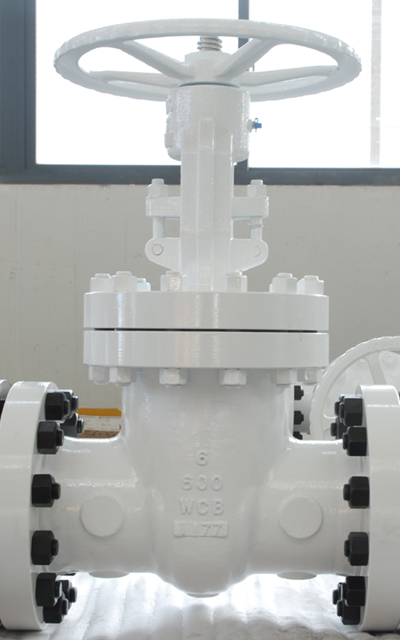

Double flanged butterfly valve also belongs to the quarter family with triple offset design. It is also lightweight and easy to operate. This butterfly valves are torque-seated valves where bubble-tight sealing is achieved when the laminar seal flexes and generates a compressive force all around the hard-faced body seat.

The materials are cast iron to ASTM A 126 Class B; ductile iron to ASTM A 536 Grade 65-45-12 / GGG40, GGG50; cast carbon steel to ASTM A 216 GR. WCB / A352 LCB / LCC; stainless steel to ASTM A 351 GR. CF8 / CF8M / CF3 / CF3M and duplex steel; aluminum bronze ASTM A148 B95500, C955800 etc.

Design and manufacture: API 609, BS 5155, MSS SP-67, EN593, MSS SP-68, GB/T12238, AWWA C504;

Testing and inspection: API 598, ISO 5208, BS 6755-I etc;

Face To Face: API 609, ANSI B 16.10, ISO 5752, DIN3202-K1, EN558-1 20 Series, BS5155, MSS SP-67 etc;

Flange Drilling: ANSI B16.5, B16.47, API 605, AWWA C207, EN1092, BS 10 Table / DIN / IS / JIS Std;

Pressure Rating: PN6, PN10, PN16, PN25, PN40, PN63, Class 150, Class 300, Class 600, Class 900.

Leakage Class: ANSI CLASS V & VI (Zero Leakage).

Operation: Up to DN150 lever operated, and above gear operated. On special request available for electric, pneumatic and hydraulic operated.

huanqiuvalve

huanqiuvalve huanqiuvalve

huanqiuvalve